If you own a mini excavator, you know the undercarriage demands consistent attention. While wear is normal, most premature damage comes from small habits and preventable issues.

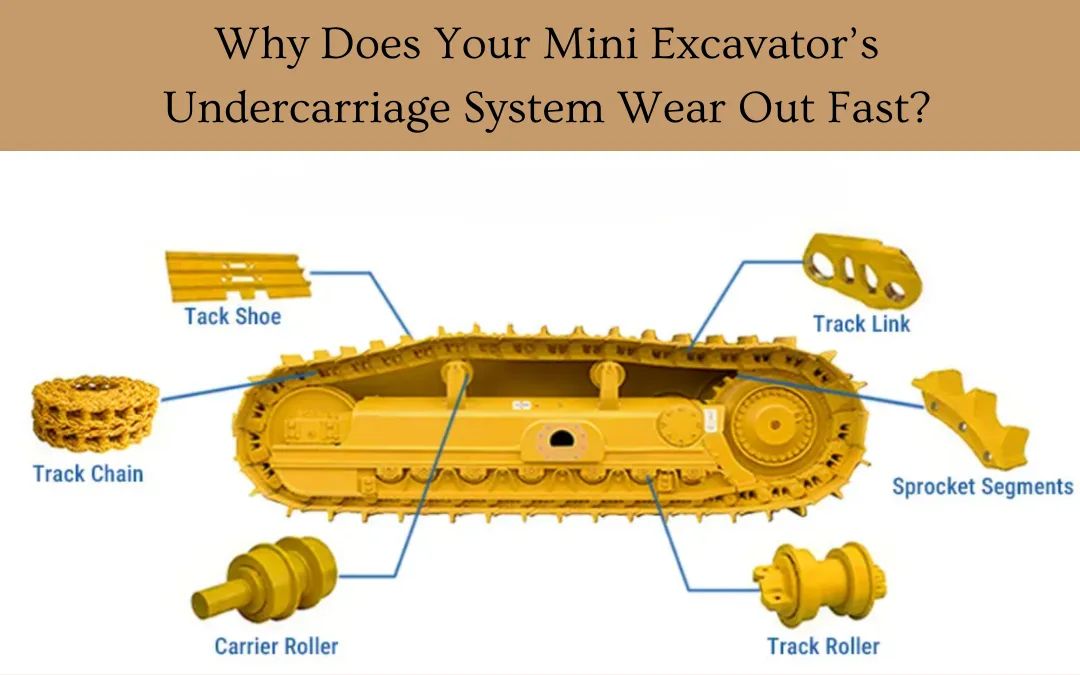

Anatomy of Undercarriage Wear

⚠️ The undercarriage is a collection of moving parts. When one wears out, it quickly speeds up the failure of the others. This is a chain reaction problem.

Rubber Tracks

Most minis use rubber tracks. Sensitive to sharp turning and impact damage. See undercarriage and track parts.

Links and Pins

Steel cables and embedded metal cores provide structural strength. Once they stretch, the whole track weakens.

Rollers and Idlers

Rollers support weight. Idlers guide the belt and hold tension. Both must spin freely.

Sprockets

Drive gears that wear quickly if the belt is too tight or contaminants are present.

The #1 Wear Factor: Incorrect Tension

❌ Too Tight

- • High stress on entire system

- • Forces links against sprockets

- • Stretches internal steel cables

- • Excessive pressure on bearings

- • Reduces fuel efficiency

⚠️ Too Loose

- • Belt lacks guidance

- • Slaps against main frame

- • Impact damage to rollers

- • Risk of "throwing a belt"

- • Costly downtime

⚙ The Golden Rule: Set Tension Based on Material

Keep it looser. Lets the belt flex and reduces friction.

Set it tighter. Stops material from packing in.

Weekly Check Required: About 1.25 to 2 inches of sag. See our maintenance guide.

Quality rubber tracks are essential for undercarriage longevity

The Abrasive Killer: Daily Cleaning

This step is non-negotiable. Wet, sticky material—clay—packs into links, rollers, and idlers. Once hard, it acts like sandpaper.

Mandatory Cleaning Routine:

- ✓ Clean undercarriage at end of every shift

- ✓ Use high-pressure washer to blast out material

- ✓ Break up large clumps with a bar or shovel

- ✓ Focus on idler area and main rails

- ✓ In freezing temps: critical—mud turns to concrete-hard ice

See our guide on operating in wet or muddy conditions.

Operational Habits That Accelerate Wear

Excessive Travel

Minimise distance. High-speed travel generates heat that accelerates wear.

Constant Sharp Turning

Counter-rotating tracks forces links sideways. Always use wider turns. Do not spin in place.

Operating on Slopes

Shifts weight unevenly. Keep drive sprocket pointed in direction of travel.

Quality rubber tracks are essential for undercarriage longevity

Proactive Inspection

Pin Wear

Check all pins. See chassis parts for replacements.

Worn Flanges

Sharp or worn edges won't guide the belt properly—increasing derail risk.

Oil Leaks

A wet roller means the seal is gone and bearing failure is imminent.

Track Condition

Check for cuts, cracks, or missing lugs. See replacement tracks.

Conclusion: Extend Your Undercarriage Life

Undercarriage wear is inevitable. But high replacement costs are not. Your daily maintenance routine and operator habits determine the lifespan.

"Make tension checks part of your weekly routine, and clean the undercarriage after each day of use."

Browse our mini excavators and spare parts.