What Every Operator Needs To Know About Bucket Pins

Excavator bucket (or attachment) pins may not be conspicuous or expensive, but they’re the unsung heroes holding your digging operation together. Understanding the different types can help you choose the most appropriate pin for your needs and improve performance and longevity. We’ll give you a concise guide breaking down the different types of pins and when to use them, and how to avoid costly mistakes.

While many different types of pins go into a mini digger, there are two main features to consider: head shape and whether they are greasable or not.

Head Shape

Oval pin buckets have two flat sides at the hole mounting point. Hex pins have six sides at the mounting point. The purpose is to stop the pin spinning when tightening the nut with a spanner. If the hole has a mismatch, the pin can be held with grips whilst the nut is tightened. Oval-head pins are easy to retain with a basic plate and bolt, not requiring a machined hex recess. Hex pins can be easier to remove with a standard socket and wrench.

Hex head-shaped pin

Oval head shaped pin top view

A rectangular pin arm style plate is suitable for situations where you need to slot it over a pin and then secure it with a lynch/linch pin through the smaller hole.

A square head pin may be used instead of an oval pin to prevent rotation when there is a flat block on the side of the hole.

You can also use a pin with no head that has holes on either side. This is used when the bosses themselves also have holes, and you can slot a lynch/linch pin through them both.

Some attachments and buckets use a universal boss design where there is no keyed shape at all, and all shapes will work.

For others, there is a boss or recess to keep the pin from turning, which means one shape will work better than the other, or one won’t work at all. Make sure to check if your attachment needs or will work better with a specific shape of pin head before purchasing new or replacement pins.

Example of a bucket with a hex-shaped recess.

Greased vs Non-Greased

Greased

Greased pins have a hole or lubrication channel (called a greaseway) that allows grease to flow from a grease nipple (zerk fitting) into the moving contact surfaces. This reduces friction and wear on the pin, excavator and attachment. This is great for the smooth operation of buckets and other attachments.

However, the channel in the pin means it is less durable than a non-greased pin. Thus, while greaseable pins are great for directly mounting attachments or a quick hitch to the excavator, it is recommended not to use them to mount buckets or other attachments to a quick hitch. It is also not recommended to use them with hydraulic breakers due to the force transmitted.

Greased pins are also slightly more difficult to manufacture and hence also slightly more expensive.

Non-Greased (Dummy) Pins

Non-greased pins, also known as dummy pins, are not hollowed out.

They are designed for use when the decreased structural integrity of lubrication channels in greasable pins makes them unsuitable, such as when a quick coupler is installed or on a hydraulic breaker.

They are often made with a softer grade of steel, allowing for wear on the pin rather than the more expensive hitch. This means they can be used as a dummy to avoid wear on more costly attachments.

Other Important Considerations

Sizing

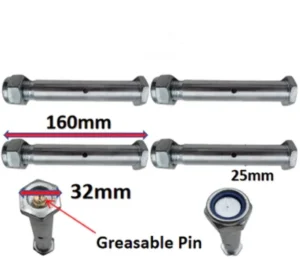

It is also important to check that the pin diameter of your bucket pins matches that of the excavator. Dog bone (also known as dumbbell pins), can also compatibility between attachments and excavators which have different pin diameters.

Wear and Tear

Wear on the pins increases the gap between the parts and can lead to decreased efficiency or damage, which can be a safety concern. It is essential to conduct periodic inspections on your pins and replace them if there are abnormal sounds in usage or if you are able to move the pins excessively. Regularly greasing your greasable pins and keeping your mini excavator out of the rain will help your pins last longer. Cleaning your mini digger of mud, dust, dirt, and other contaminants can also help reduce corrosion and abrasion to the pins.